Innovative Factory Solutions: The Compact SLAM AMR Robot

Revolutionizing Factory Operations with SLAM AMR Robots

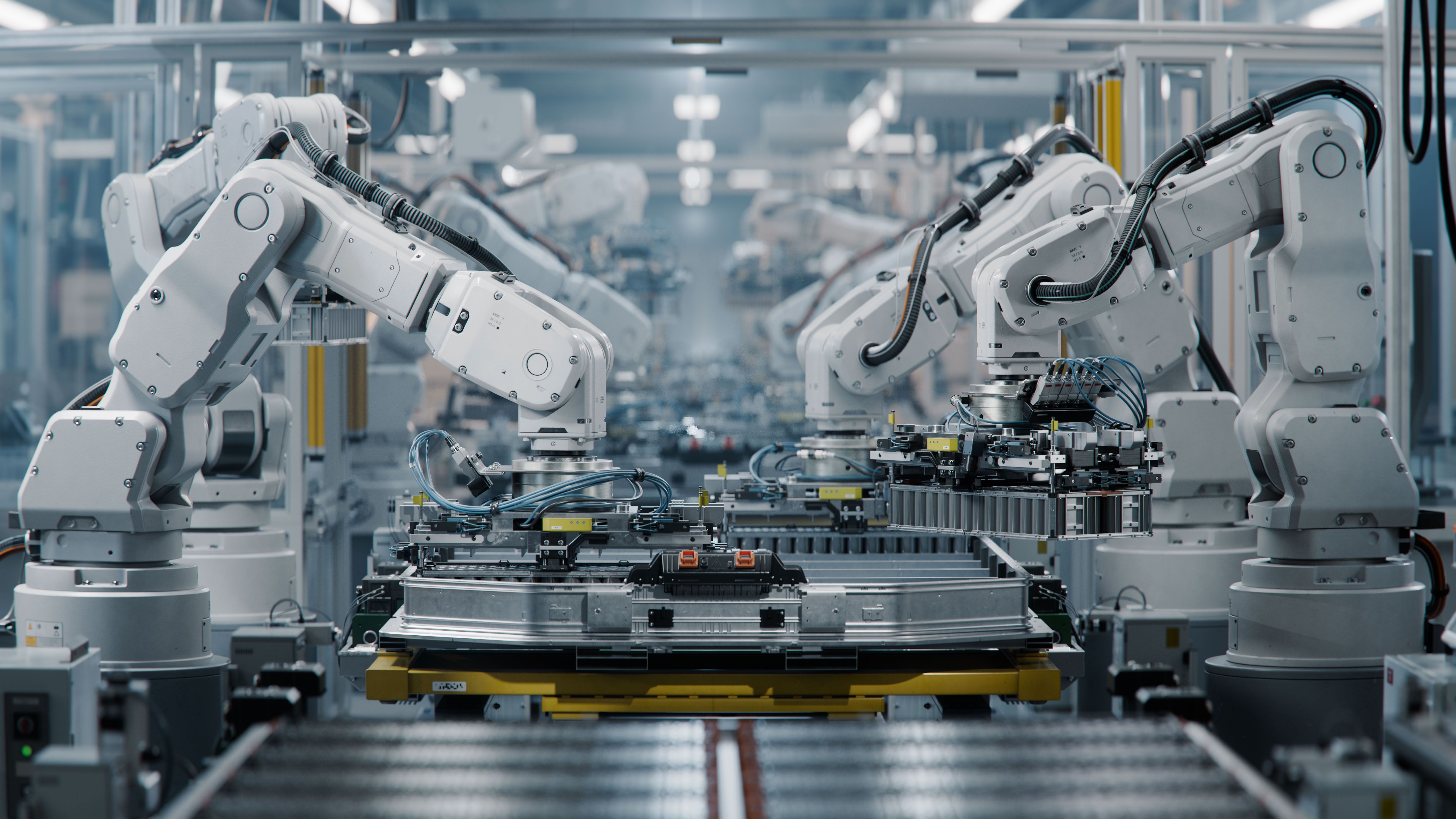

In the rapidly evolving world of manufacturing, the demand for efficiency and precision is higher than ever. Companies are continuously seeking innovative solutions to enhance their production lines and streamline operations. One such groundbreaking development is the introduction of the Compact SLAM AMR Robot, which is setting new standards in factory automation.

The Compact SLAM AMR Robot, short for Simultaneous Localization and Mapping Autonomous Mobile Robot, leverages cutting-edge technology to navigate complex environments without the need for external guidance systems. This ability makes it an ideal solution for factories looking to optimize their logistics and material handling processes.

Unmatched Precision and Flexibility

One of the standout features of the SLAM AMR Robot is its unparalleled precision in navigation. By combining data from sensors with advanced algorithms, these robots can create real-time maps of their surroundings. This capability allows them to move seamlessly through dynamic environments, avoiding obstacles and adjusting routes as necessary.

Moreover, the flexibility offered by SLAM AMR Robots is transformative for factory floors. Unlike traditional automated guided vehicles (AGVs), which require predefined paths, these robots can adapt to changes in layout, ensuring uninterrupted operations even when the factory floor is reconfigured.

Enhancing Efficiency and Reducing Costs

Implementing SLAM AMR Robots in a factory setting can significantly boost efficiency. By automating routine tasks such as material transport and inventory management, these robots free up human workers to focus on more complex tasks that require critical thinking and creativity. This shift not only enhances productivity but also reduces operational costs over time.

Businesses adopting SLAM AMR technology are witnessing substantial improvements in workflow efficiency. The robots' ability to operate 24/7 without fatigue or errors leads to faster turnaround times and minimized downtime.

Integration and Scalability

The ease of integrating SLAM AMR Robots into existing systems is another key advantage. These robots can be seamlessly incorporated into a variety of industries with minimal disruption. Additionally, their modular design allows for easy scalability, catering to both small-scale operations and large manufacturing setups.

With an intuitive interface and user-friendly software, managing a fleet of SLAM AMR Robots becomes straightforward. Factory managers can monitor and control multiple units from a central system, enabling coordinated efforts across different departments.

Future Prospects in Automation

As technology continues to advance, the potential applications for SLAM AMR Robots are expanding. From warehouses to assembly lines, these robots are positioned to become a staple in modern manufacturing environments. Their ability to learn and adapt over time promises even greater efficiencies and innovations in the future.

The Compact SLAM AMR Robot represents a significant leap forward in factory automation, offering a glimpse into a future where robotics play a central role in industrial processes. For companies looking to stay competitive, embracing this technology could be the key to unlocking new levels of productivity and success.

Lifting Height AGV Robot Compact Structure Slam AMR Robot 50mm for Factory Handling