The Evolution and Importance of Ink in Printing

The Early Beginnings of Ink in Printing

The history of ink is as ancient as the art of writing itself. Historically, ink was made from natural resources such as plants, minerals, and even animal byproducts. In early printing, such as woodblock printing in China, inks were crafted using soot and animal glue, creating a rudimentary yet effective medium for transferring images and text onto paper.

The invention of the printing press by Johannes Gutenberg in the 15th century marked a revolutionary phase in the use of ink. This era witnessed the development of oil-based inks, which were more suited for the metal type used in printing presses. These inks allowed for sharper text and images, effectively laying the groundwork for modern printing techniques.

Technological Advancements in Ink Composition

As technology advanced, so did the composition and functionality of inks. The 19th and 20th centuries saw significant breakthroughs with the introduction of synthetic dyes and pigments. These innovations allowed for a broader spectrum of colors and greater consistency in print quality, making ink a pivotal component in the burgeoning printing industry.

The development of offset printing further pushed the evolution of ink. Offset printing, which involves transferring an inked image from a plate to a rubber blanket and then onto the printing surface, required inks with precise viscosity and drying properties. This innovation led to the creation of inks that could rapidly dry while maintaining vibrant colors.

The Role of Ink in Digital Printing

In recent decades, digital printing has transformed the way ink is used. Unlike traditional methods, digital printing does not require printing plates. Instead, it uses digital files to directly apply ink to substrates. This method demands inks that are compatible with a variety of digital printers, including inkjet and laser printers.

Inkjet printers, in particular, have spurred the development of specialized inks that are designed to produce high-quality images with fine detail. These inks must be capable of quick drying to prevent smudging while providing a wide color gamut for vivid prints.

Environmental Considerations in Ink Production

With growing awareness about environmental sustainability, the production and formulation of ink have also evolved to reduce ecological impact. Many manufacturers now prioritize eco-friendly inks made from renewable resources or those that are biodegradable or water-based.

The push towards sustainability is evident in the increasing use of soy-based inks and other vegetable-based alternatives. These inks not only reduce reliance on petroleum-based products but also offer benefits such as easier recycling and reduced VOC emissions.

The Future of Ink in Printing

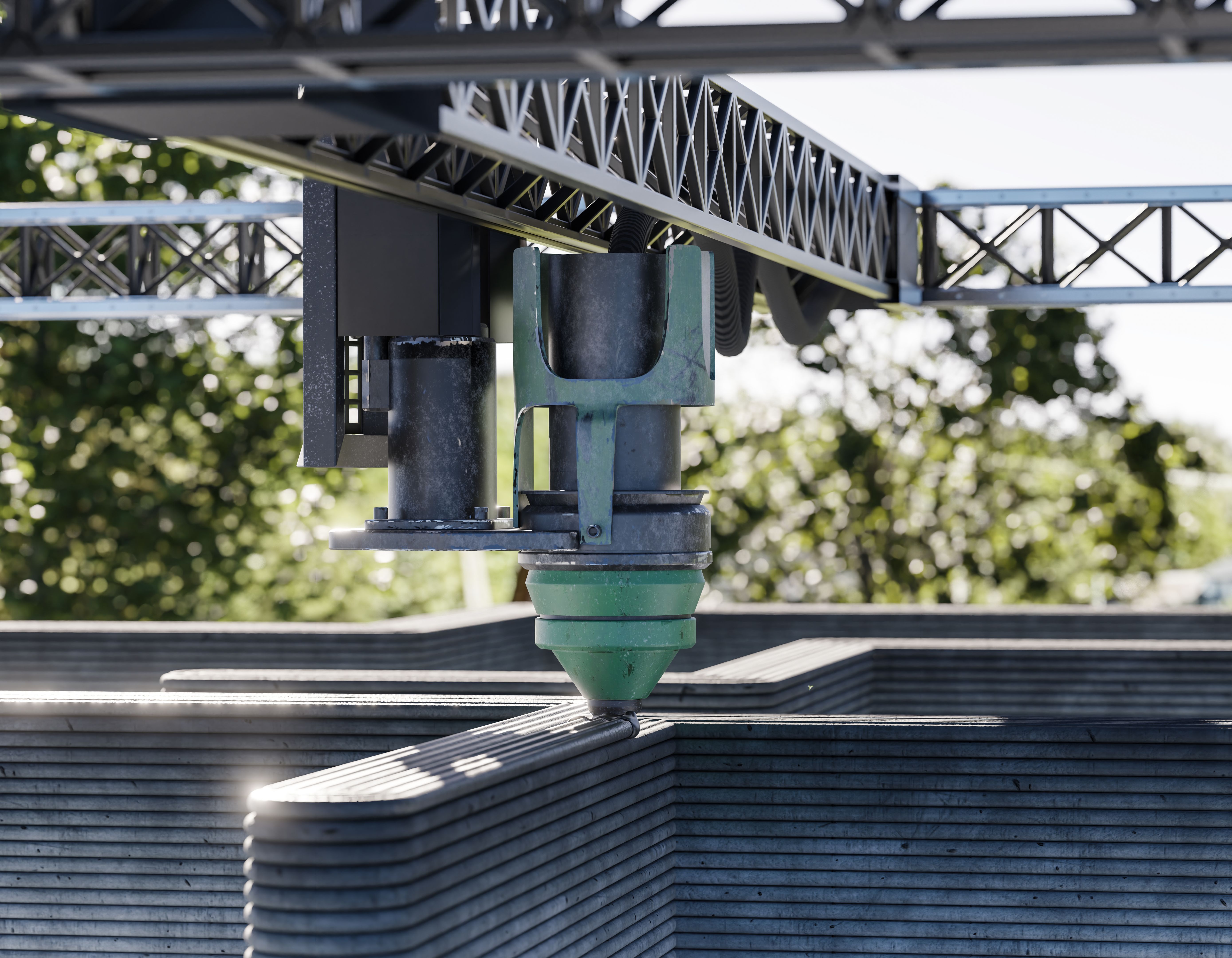

As technology continues to advance, the future of ink looks promising with emerging trends such as conductive inks for printed electronics and 3D printing inks. Conductive inks enable the creation of flexible electronics by allowing circuits to be printed on a variety of substrates.

In 3D printing, specialized inks, often referred to as filaments or resins depending on the technology used, are crucial in building complex structures layer by layer. The continuous innovation in this field suggests that ink will remain a cornerstone in both traditional and cutting-edge printing technologies.

Commercial Kitchen Marketplace

Your one-stop online destination for equipping professional kitchens. Discover a wide selection of durable, high-quality commercial-grade appliances, from heavy-duty ovens and refrigeration units to efficient food preparation tools and essential kitchenware. Visit our store: http://avice.org